Due to its highly dangerous outcome, the term ‘arc flash’ is widely recognized within the

electrical industry as a hazardous event that must be prevented. A search in the Occupational

Safety and Health Administration (OSHA) accident report database reveals over 1,400 incidents

related to arc flash in recent years, many of which have resulted in serious injuries or fatalities.

An arc flash is a sudden and intense release of electrical energy that occurs when electricity

deviates from its intended path and arcs through the air to an unintended conductor. An arc

flash produces a powerful burst of heat, light, and sound, posing a significant hazard to

personnel in the vicinity. Given the potentially fatal consequences of an arc-flash incident,

complying with the National Fire Protection Association (NFPA) and establishing safe working

distances around exposed live electrical conductors is critical for minimizing risk, preventing

severe injuries, and ultimately saving lives.

To fully understand the severity of arc flash hazards, it is important to examine the

associated risks. Among the most significant are severe burn injuries. Arc flash events can

reach temperatures as high as 35,000 degrees Fahrenheit, hot enough to vaporize metal. The

impact on human senses can be devastating, with extreme light intensity and sound pressure

levels far exceeding safe exposure limits. These conditions can result in temporary or even

permanent blindness and hearing loss. Additionally, the superheated air generated by an arc

flash can cause serious respiratory injuries, including airway damage. Furthermore, smoke

inhalation from the combustion of materials present becomes a risk factor. Fortunately, the

NFPA provides clearly defined safe working distances. When properly followed, these

guidelines play an important role in mitigating the dangers associated with arc flash incidents.

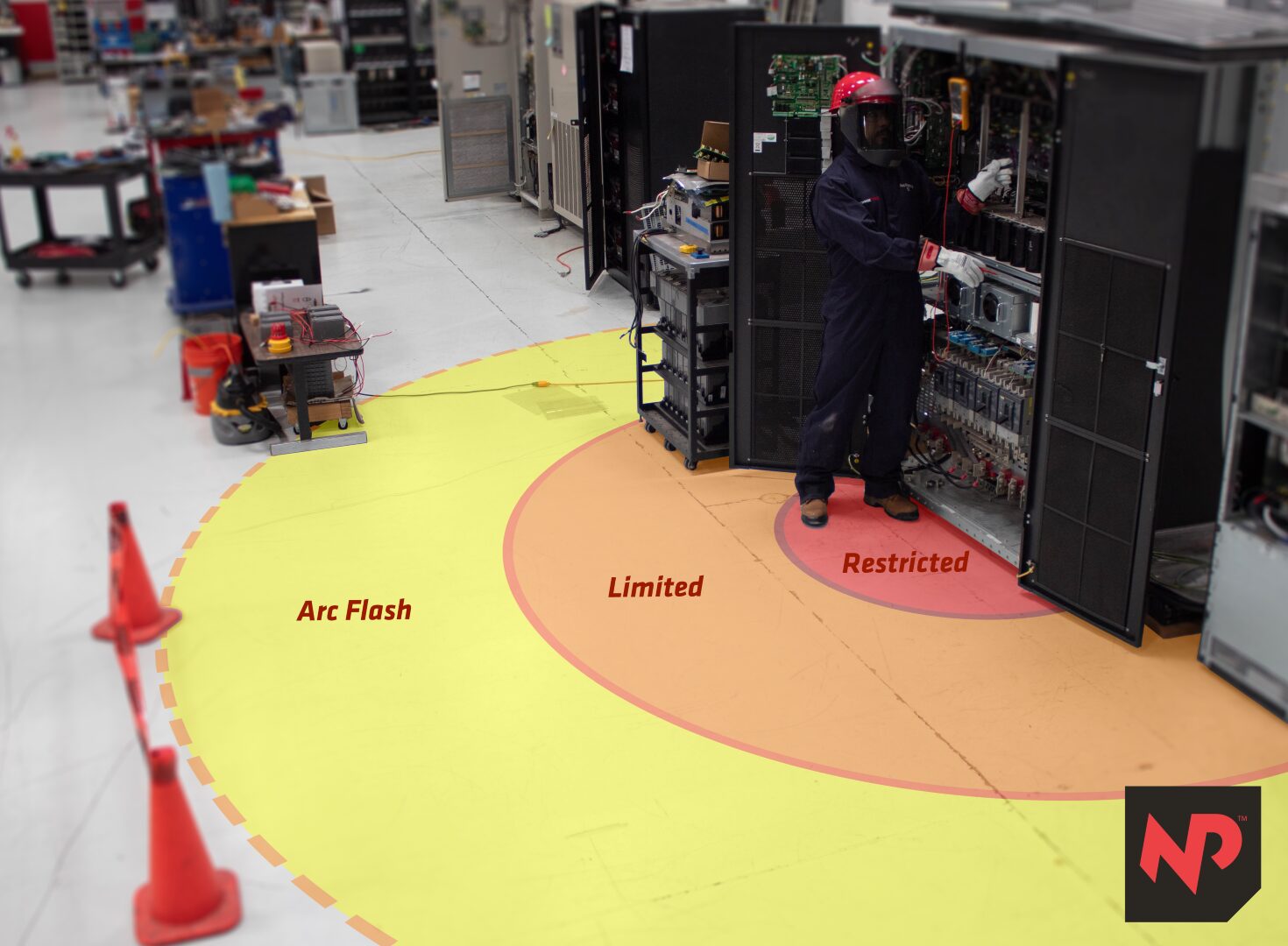

To help assess and manage the risk of electrical hazards based on proximity to exposed

energized conductors, the NFPA-70E standard outlines specific Boundaries for both AC and DC

voltage systems. At the highest level of risk is the Restricted Approach Boundary. Entry into this

zone is limited to qualified personnel who are trained and equipped with the appropriate

personal protective equipment (PPE). This area presents the greatest potential for electric

shock, and unqualified individuals must not enter under any circumstances. While the boundary

may be just a few feet for lower voltages, it increases proportionally with higher voltage levels.

Beyond this is the Limited Approach Boundary, where the risk of electric shock remains.

Unqualified workers may enter this area only under the direct supervision of a qualified

individual. Although this boundary is set at a greater distance than the restricted zone, it still

poses significant hazards and must be treated with caution. The last zone is the Arc Flash

Boundary. This boundary defines the distance at which a person without adequate PPE could

sustain a second-degree burn in the event of an arc flash. Such burns are comparable to

touching a surface of 140 degrees Fahrenheit for 3 seconds, often resulting in blistering and

intense pain. The Arc Flash Boundary is a critical safety threshold and must always be

respected. Whenever there is a potential for arc flash, it is important to consult the NFPA-70E

Electric Shock Protection Approach Boundaries table to determine safe working distances.

In closing, the potentially fatal consequences of arc flash incidents highlight the critical

importance of adhering to the NFPA’s prescribed safe working distances around exposed live

electrical conductors. As Benjamin Franklin once said, “An ounce of prevention is worth a pound

of cure”. When maintenance or inspection requires access to energized components, strict

compliance with these guidelines is essential to minimizing risk, preventing serious injuries, and

ensuring the safety of personnel in electrical work environments.

Written By:

David Paiz

Training and Technical Support Manager

Environmental, Health, and Safety