News Article

Why Wait

WHY WAIT?

More and more critical power customers, whether their critical power assets are managed by a representative of their IT, Facilities, or Procurement department are adopting the “we’ll fix it when it breaks” mentality. The cost to maintain their critical power equipment, namely the UPS, is being lumped into the overall cost saving strategy of the business. This ultimately puts the reliability of the critical power infrastructure at risk and is a very dangerous and potentially costly practice.

Throughout my years as a critical power instructor, I have often referenced the automotive industry as being similar to the UPS industry: there are multiple makes and models, there may be more parts available for one make over another, there are customer preferences to contend with, and there are the varying Subject Matter Experts’ for each make. In continuing this reference, I will use it as it applies to the upkeep of one’s vehicle.

If the vehicle you drive on a daily basis needs new tires because they are bald, how long would you drive on those tires? Would you:

- Simply replace all the tires?

- Replace the worst tire first and work your way through the whole set one at a time, in hopes to get through them all before one blows-out?

- Hope you don’t have a blow-out as you continue to drive with the tires while saving enough money to replace all of them?

- Wait until you finally have a blow-out, and then replace the one that failed?

In the case of your vehicle, would you risk your safety and the safety of others by ignoring a known risk? Now, imagine the tires as the batteries in your UPS system. Would you risk the potentially high cost of lost data and revenue or employee downtime? In cases of Life Safety and Health applications, would you even risk human life?

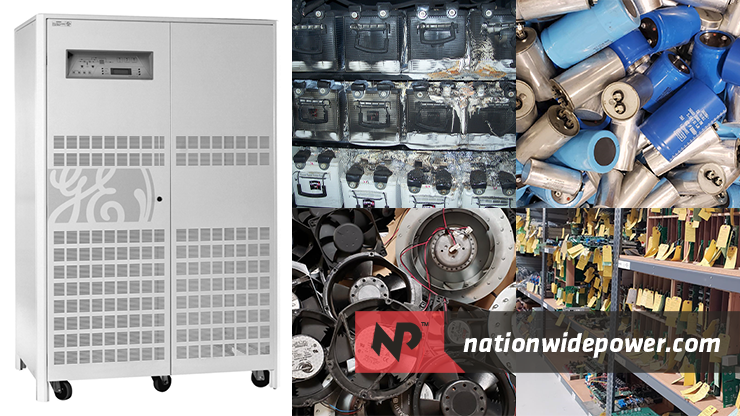

One may be surprised to find that due to not wanting to spend money, a lot of companies would rather wait for the blow-out! Whether they are old batteries, capacitors, or fans, the parts still pose a risk. The risk is ignored, however so long as the UPS unit is still running. This is very similar to the vehicle that may still be able to drive down the road with bald tires.

The average VRLA battery replacement costs $3,000 to $6,000 for one string of batteries. In comparison, the average cost of a data center outage caused by a failed battery string meets or exceeds the cost of the replacement. These costs may include other outage ramifications, such as a lack of confidence from customers, recovery time, unforeseen labor costs, potential generator fuel costs, etc.

We encourage our clients to consider the true cost of downtime to their organization when evaluating the cost of preventive maintenance and upkeep of their UPS.

At Nationwide Power, we understand that not every business is able to use capital funds immediately upon manufacturer-based recommendations. There is however, a distinct difference between waiting for budgetary reasons and opting out of preventive maintenance altogether due to cost cutting measures.

Lastly, when preventive UPS maintenance is routinely performed, our Critical Power Professionals can proactively notify our customers of upcoming larger expenses. This provides more time for budgetary planning and less risk for your business. However, even after all critical recommendations have been made, there really is only one question that remains to be answered:

Why wait?

Need Preventive Maintenance?

[et_social_share]

[et_social_share]

Latest News

The Winter Advantage: Why Replacing UPS Batteries During Winter Is a Smart Move

News Article As the winter season approaches, it's an ideal time to contemplate the maintenance of your Uninterruptible Power Supplies (UPS) and, more specifically, the replacement of UPS batteries. UPS systems are a crucial component of safeguarding your...

Nationwide Power Honored as a Top Workplace for the Second Consecutive Year

News Article Corks are popping, and the excitement is overflowing at Nationwide Power as we celebrate a remarkable achievement. For the second year in a row, our organization has been named a Top Workplace, solidifying our position as a leader in creating a culture of...

Case Study #156 | Importance of Following Age Based Recommendations

Case StudyIn this Nationwide Power™ (NP™) case study, we highlight the importance of following your service provider’s age-based components. The most common age-based components are batteries (every 3-5 years), fans (every 5 years), capacitors (every 5-7 years), and...

Newsletter Signup

0 Comments