Case StudyNationwide Power™ (NP™) is the leading provider in the critical power supply industry. Our core business is the sales and service of uninterruptible power supplies and UPS batteries. Our 57,000 square foot warehouse, with over $10 million in parts and...

Why Wait

News Article

Why Wait

WHY WAIT?

More and more critical power customers, whether their critical power assets are managed by a representative of their IT, Facilities, or Procurement department are adopting the “we’ll fix it when it breaks” mentality. The cost to maintain their critical power equipment, namely the UPS, is being lumped into the overall cost saving strategy of the business. This ultimately puts the reliability of the critical power infrastructure at risk and is a very dangerous and potentially costly practice.

Throughout my years as a critical power instructor, I have often referenced the automotive industry as being similar to the UPS industry: there are multiple makes and models, there may be more parts available for one make over another, there are customer preferences to contend with, and there are the varying Subject Matter Experts’ for each make. In continuing this reference, I will use it as it applies to the upkeep of one’s vehicle.

If the vehicle you drive on a daily basis needs new tires because they are bald, how long would you drive on those tires? Would you:

- Simply replace all the tires?

- Replace the worst tire first and work your way through the whole set one at a time, in hopes to get through them all before one blows-out?

- Hope you don’t have a blow-out as you continue to drive with the tires while saving enough money to replace all of them?

- Wait until you finally have a blow-out, and then replace the one that failed?

In the case of your vehicle, would you risk your safety and the safety of others by ignoring a known risk? Now, imagine the tires as the batteries in your UPS system. Would you risk the potentially high cost of lost data and revenue or employee downtime? In cases of Life Safety and Health applications, would you even risk human life?

One may be surprised to find that due to not wanting to spend money, a lot of companies would rather wait for the blow-out! Whether they are old batteries, capacitors, or fans, the parts still pose a risk. The risk is ignored, however so long as the UPS unit is still running. This is very similar to the vehicle that may still be able to drive down the road with bald tires.

The average VRLA battery replacement costs $3,000 to $6,000 for one string of batteries. In comparison, the average cost of a data center outage caused by a failed battery string meets or exceeds the cost of the replacement. These costs may include other outage ramifications, such as a lack of confidence from customers, recovery time, unforeseen labor costs, potential generator fuel costs, etc.

We encourage our clients to consider the true cost of downtime to their organization when evaluating the cost of preventive maintenance and upkeep of their UPS.

At Nationwide Power, we understand that not every business is able to use capital funds immediately upon manufacturer-based recommendations. There is however, a distinct difference between waiting for budgetary reasons and opting out of preventive maintenance altogether due to cost cutting measures.

Lastly, when preventive UPS maintenance is routinely performed, our Critical Power Professionals can proactively notify our customers of upcoming larger expenses. This provides more time for budgetary planning and less risk for your business. However, even after all critical recommendations have been made, there really is only one question that remains to be answered:

Why wait?

Need Preventive Maintenance?

[et_social_share]

[et_social_share]

Latest News

Case Study #153 | DIRFT (Doing It Right the First Time)

Case Study #152 | The Importance of the Critical Power Environment

Case Study In this Nationwide Power™ Case Study, we show the importance of a controlled environment and how one can never be over-prepared for the unexpected. This case study specifically looks at the Eaton/Powerware 9330-30kVA UPS. Product Eaton/Powerware 9330-30kVA...

Case Study #151 | The Cost of Deferred Maintenance

Case Study In this Nationwide Power™ Case Study, we show the importance of performing preventive maintenance and completing recommendations. This case study is about a Mitsubishi 9900A 150kVA UPS. After several attempts over the course of many months trying to...

Newsletter Signup

UPS System & Battery Replacement and Recycling

News Article

UPS System & Battery Replacement and Recycling

The fastest growing waste streams in the industrialized world are discarded electronics equipment due to the growing use of these products. In the UPS industry, companies do their part to help reduce the carbon footprint and support a cleaner, more sustainable environment by recycling, reducing and reusing old UPS systems and spent batteries.

Depending on the age, size, brand and condition, used UPS systems can be refurbished and/or recycled. By government and industry regulations, spent and expired batteries are disposed and recycled Per EPA regulations.

Battery Council International (BCI) – “Lead Battery Recycling Process”

Why is it important to your business?

- Reclaiming and reusing valuable components from the UPS system.

- Protects the environment from dangers of toxic contaminations.

- Conserving natural resources such as metals and minerals.

- Reduce risk of UPS system failure and unplanned downtime.

- Fewer emergency repairs.

- Minimize downtime and maximize value.

Nationwide Power recycles as many components of old UPS parts as are economically feasible without causing further environmental damage. This equipment is broken down by material type and recycled in bulk.

All UPS batteries are recycled according to EPA (Environment Protection Agency) and industry regulations. The spent and expired batteries are recycled in bulk and then used as a raw material input for other products.

Nationwide Power helps customers find new equipment that uses energy saving technologies and improve efficiencies. We also provide UPS battery and equipment recycling services to customers at no additional cost.

In addition, we are actively reducing the usage of paper, postage and other materials by electronically corresponding with customers and vendors which reduces our carbon footprint.

How Nationwide Power can help you support a cleaner, more sustainable environment?

[et_social_share]

[et_social_share]

Latest News

Case Study #153 | DIRFT (Doing It Right the First Time)

Case StudyNationwide Power™ (NP™) is the leading provider in the critical power supply industry. Our core business is the sales and service of uninterruptible power supplies and UPS batteries. Our 57,000 square foot warehouse, with over $10 million in parts and...

Case Study #152 | The Importance of the Critical Power Environment

Case Study In this Nationwide Power™ Case Study, we show the importance of a controlled environment and how one can never be over-prepared for the unexpected. This case study specifically looks at the Eaton/Powerware 9330-30kVA UPS. Product Eaton/Powerware 9330-30kVA...

Case Study #151 | The Cost of Deferred Maintenance

Case Study In this Nationwide Power™ Case Study, we show the importance of performing preventive maintenance and completing recommendations. This case study is about a Mitsubishi 9900A 150kVA UPS. After several attempts over the course of many months trying to...

Newsletter Signup

How important is it to have regular UPS Maintenance performed?

News Article

How important is it to have regular UPS Maintenance performed?

UPS Systems are complex pieces of highly technical electronic equipment and need regular preventive maintenance (PM). The maintenance intervals can vary from one to four PM inspections per year or in some cases, even monthly.

The top main causes for UPS equipment failure are:

- Batteries – the main component of any UPS. Batteries require at least an annual inspection and maintenance regardless of their age or warranty status.

- Capacitors – electrical devices that stores and releases electrical energy. Similar to batteries, capacitors will degrade over time.

- Fans – some run on their own electrical or mechanical restrictions.

Why is it important to your business?

Regular preventive maintenance is the single most cost-effective method to optimize the life expectancy and performance of UPS equipment. It is just as important in choosing the right maintenance company to oversee the ongoing condition of the UPS equipment and components. Look for a well-qualified and trained service company with a well-documented track record and reputation and one that specializes in servicing UPS equipment and components. Clearly define the maintenance tasks to be completed by trained and experienced UPS Field Service Engineer.

Regular serviced and managed UPS maintenance will:

- Maximize Uptime

- Reduce outages and accidents

- Improve energy efficiency

- Decrease operating costs

- Prolong the life of the UPSs

- Avoid common risks

Recommended Preventive Maintenance for UPS Components*

| Batteries | Standby use: Inspect semi-annually Replace VRLA batteries every 3 to 5 years Replace wet cell batteries as needed |

Cycle use: 1200 cycles at 30% of discharge 550 cycles at 50% of discharge 250 cycles at 100% of discharge |

| Capacitors | Inspect annually Replace every 5 to 7 years |

|

| Fans | Verify annually Replace every 7 years |

|

| Air Filters | Inspect monthly Replace as needed |

|

| Lug Terminals | For all mechanical power lugs, have an annual visual and thermal inspection |

*Every UPS contains high-wear consumable components that must be replaced according to the manufacturer’s specifications.

A UPS system has many electrical and mechanical components. It’s important your critical equipment should be serviced regularly and maintained by a skilled and trained technician. Regular preventive maintenance practices reduce the risk of downtime, outages and accidents.

When was the last time your UPS system was serviced and maintained? If it’s been more than 12 months, then it’s time to have your UPS inspected.

Need Preventive Maintenance?

[et_social_share]

[et_social_share]

Latest News

Case Study #153 | DIRFT (Doing It Right the First Time)

Case StudyNationwide Power™ (NP™) is the leading provider in the critical power supply industry. Our core business is the sales and service of uninterruptible power supplies and UPS batteries. Our 57,000 square foot warehouse, with over $10 million in parts and...

Case Study #152 | The Importance of the Critical Power Environment

Case Study In this Nationwide Power™ Case Study, we show the importance of a controlled environment and how one can never be over-prepared for the unexpected. This case study specifically looks at the Eaton/Powerware 9330-30kVA UPS. Product Eaton/Powerware 9330-30kVA...

Case Study #151 | The Cost of Deferred Maintenance

Case Study In this Nationwide Power™ Case Study, we show the importance of performing preventive maintenance and completing recommendations. This case study is about a Mitsubishi 9900A 150kVA UPS. After several attempts over the course of many months trying to...

Newsletter Signup

Eaton’s New Product : 9PX UPS (700 – 1500 VA)

News Article

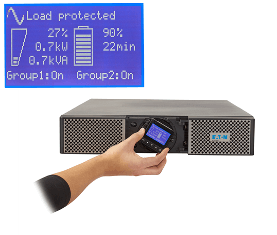

Eaton’s New Product : 9PX UPS (700 – 1500 VA)

Eaton continues to expand the 9PX UPS portfolio which will provide industry-leading features in capacity, efficiency and usability. Eaton’s newest products: 9PX UPS – 700, 1000 and 1500 VA models will make it easier than ever for companies to protect their IT environments.

Eaton 9PX UPS Features:

• Graphical LCD interface with easy-to-read local menu

• Extended Battery Life with ABM® Technology to keep batteries cool and extend their lifetime up to 50%

• Power more for less and operate green with up to 93% efficiency in online mode

• Double-conversion topology for constant power condition monitoring

• Rack/ Tower versatility

The newest 9PX UPS (700, 1000, 1500 VA) are now available.

GRAPHICAL LCD INTERFACE ROTATES

HOT-SWAPPLE BATTERIES

RACK/TOWER (RT) AND EXTENDED BATTERY MODULE (EBM)

[et_social_share]

[et_social_share]

Latest News

Case Study #153 | DIRFT (Doing It Right the First Time)

Case StudyNationwide Power™ (NP™) is the leading provider in the critical power supply industry. Our core business is the sales and service of uninterruptible power supplies and UPS batteries. Our 57,000 square foot warehouse, with over $10 million in parts and...

Case Study #152 | The Importance of the Critical Power Environment

Case Study In this Nationwide Power™ Case Study, we show the importance of a controlled environment and how one can never be over-prepared for the unexpected. This case study specifically looks at the Eaton/Powerware 9330-30kVA UPS. Product Eaton/Powerware 9330-30kVA...

Case Study #151 | The Cost of Deferred Maintenance

Case Study In this Nationwide Power™ Case Study, we show the importance of performing preventive maintenance and completing recommendations. This case study is about a Mitsubishi 9900A 150kVA UPS. After several attempts over the course of many months trying to...

Newsletter Signup

Emerson Network Power is now Vertiv™

News Article

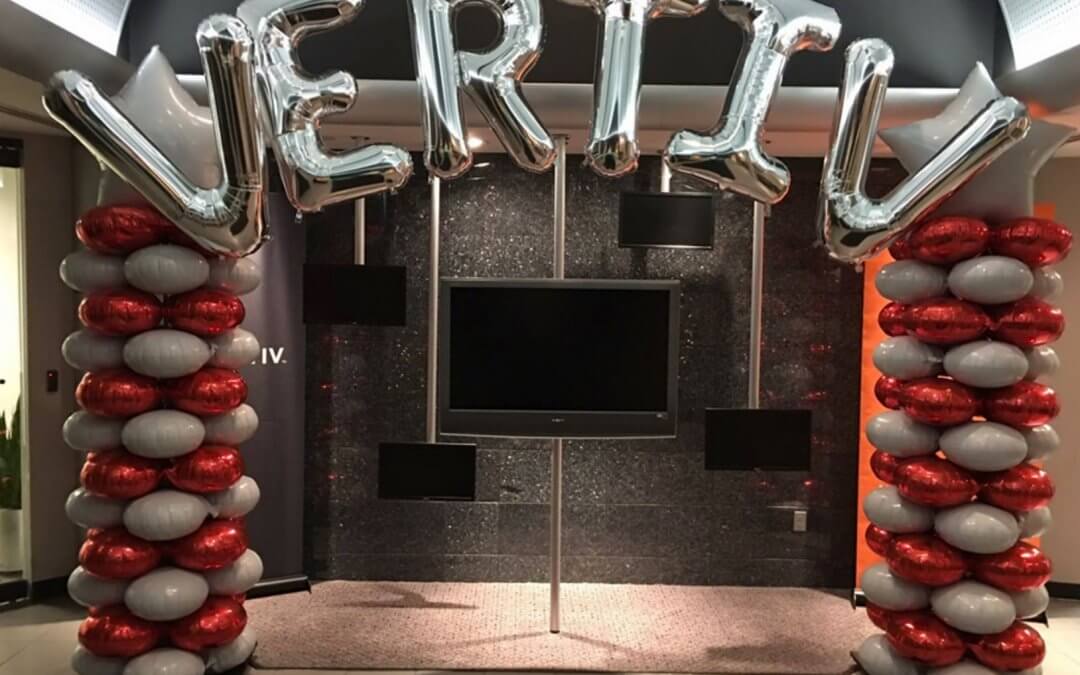

Emerson Network Power is now Vertiv™

In August 2016, Emerson announced an agreement to sell its Network Power business to Platinum Equity for $4 billon. The sale was completed earlier this month. In April, Emerson Network Power announced their new company name would be Vertiv™. The combination of two words “vertex” and “active” representing how the company will help its customers reach their peak, and the more nimble and more evolved company they’re becoming.

Earlier this month, Vertiv officially announced their newly appointed CEO, Rob Johnson, a veteran of APC (American Power Conversion) at the time it was purchased by Schneider Electric in 2007.

Vertiv designs, manufacturers and services mission critical technologies for data centers, communication networks and commercial and industrial facilities. With more than 20,000 employees, global offices and facilities around the world, the company is headquartered in Columbus, Ohio, USA.

Why this is important to your business:

Vertiv will focus their technology in the critical power industry by innovating and developing their applications in data centers, communication networks and commercial and industrial facilities.

Vertiv will continue to build on their current product portfolio: ASCO®; Chloride®; Liebert®; NetSure™; Trellis™

Emerson retained a subordinated interest in the newly branded company, Vertiv.

To read more:

Emerson Network Power Rebrands as Vertiv, Appoints New CEO

Image Source: Matt Dean, General Counsel, Vertiv Co.

[et_social_share]

[et_social_share]

Latest News

Case Study #153 | DIRFT (Doing It Right the First Time)

Case StudyNationwide Power™ (NP™) is the leading provider in the critical power supply industry. Our core business is the sales and service of uninterruptible power supplies and UPS batteries. Our 57,000 square foot warehouse, with over $10 million in parts and...

Case Study #152 | The Importance of the Critical Power Environment

Case Study In this Nationwide Power™ Case Study, we show the importance of a controlled environment and how one can never be over-prepared for the unexpected. This case study specifically looks at the Eaton/Powerware 9330-30kVA UPS. Product Eaton/Powerware 9330-30kVA...

Case Study #151 | The Cost of Deferred Maintenance

Case Study In this Nationwide Power™ Case Study, we show the importance of performing preventive maintenance and completing recommendations. This case study is about a Mitsubishi 9900A 150kVA UPS. After several attempts over the course of many months trying to...

Newsletter Signup

Rising Lead Prices in 2017

News Article

Rising Lead Prices in 2017

Batteries are the most critical component to an UPS system. A weak or bad battery makes an UPS interruptible. All it takes is one weak or aging battery to expose your critical equipment to a power problem. The cost of keeping your batteries fresh and providing regular maintenance inspections on them is minimal, when compared to the cost of downtime that a single battery can cause.

We are hearing from our suppliers that the price of lead is expected to increase anywhere between 5% – 15% in 2017. Prices will start increasing as current inventory is depleted, so don’t delay.

Nationwide Power is available to support customers by getting a head start for anyone looking to replace their UPS batteries before the prices increase in 2017.

Should you have any questions, please feel free to contact us at 800-868-2780 or click here to request a Quick Quote for Battery Replacement.

Read more:

Reuters: METAL – Lead rises to 16-month high on tighter supply, nickel slips

London Metal Exchange (LME): Historical price graph for Lead

[et_social_share]

[et_social_share]

Latest News

Case Study #153 | DIRFT (Doing It Right the First Time)

Case StudyNationwide Power™ (NP™) is the leading provider in the critical power supply industry. Our core business is the sales and service of uninterruptible power supplies and UPS batteries. Our 57,000 square foot warehouse, with over $10 million in parts and...

Case Study #152 | The Importance of the Critical Power Environment

Case Study In this Nationwide Power™ Case Study, we show the importance of a controlled environment and how one can never be over-prepared for the unexpected. This case study specifically looks at the Eaton/Powerware 9330-30kVA UPS. Product Eaton/Powerware 9330-30kVA...

Case Study #151 | The Cost of Deferred Maintenance

Case Study In this Nationwide Power™ Case Study, we show the importance of performing preventive maintenance and completing recommendations. This case study is about a Mitsubishi 9900A 150kVA UPS. After several attempts over the course of many months trying to...

Newsletter Signup